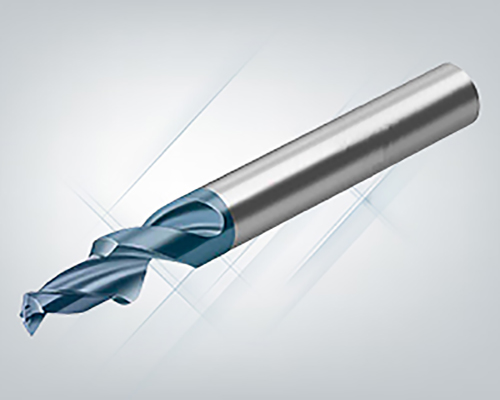

Solid Carbide Step Drills

Expertise :

- Dual diamiter and angled design allows for custom froms to be crited with a single operation

- Helps in redusign cycle time and number of tools needed

- Available in solid and throuwgh coolant design

- Tool available with multiple flutes

- Ideal for drilling tap holes with countersink

Description

Step drill—JP TECH TOOLS offers a complete range of Solid carbide drill that offers a one-pass solution in steels and irons and reduce cycle time and increase productivity. A step drill also has the ability of chamfering and de-burring the cutting edge of work-piece by using the level of the next step. The highly polished surface ensures superior chip evacuation even when low-pressure coolant is applied.

Drill machining tools used for making round holes in solid material. Drilling tools are End cutting tools designed for producing holes in work piece.

APPLICATION IN INDUSTRIES –

- AUTOMOBILE INDUSTRY

- MARINE INDUSTRY

- MANUFACTURING SECTORS

- RAILWAY INDUSTRY

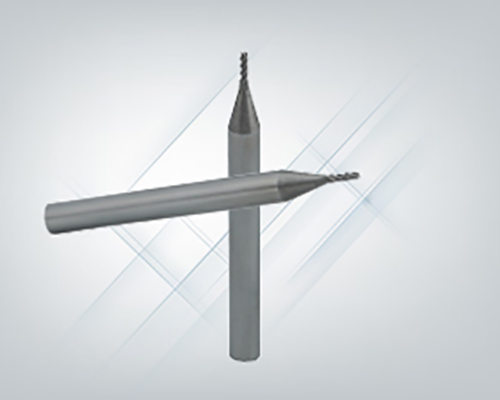

Micro Drills

Expertise :

- Micro drills are excellent for producing smooth holes.

- Can drill through all hard metals robustly.

- Proven to help prevent drill walking.

- Helps to get precise holes.

Description

Micro-drill—JP TECH TOOLS micro-drill are excellent for producing precision holes through all hard metal with excellent chip control and also helps to reduce cycle time with the help of our distinct geometry

JP TECH TOOLS offers this high precision carbide micro drill from range of 0.20mm to 3.0mm diameter

APPLICATION IN INDUSTRIES-

- MEDICAL INDUSTRIES

- MANUFACTURING SECTORS

- MARINE INDUSTRY

- JEWELRY INDUSTRY

Solid Carbide TCH Drills

Expertise :

- Burnishing margin helps to create smooth hole.

- Special coating increases tool life.

- High accuracy.

- Axial run-out of less than 2 micron.

Description

Burnishing drill— JP TECH TOOL’S burnishing drills allows very accurate sizing of the hole and the burnishing margins create a very fine finish on the inside of the hole. JP TECH TOOLS’ drills are extremely precise when you need multiple holes that are very close in size to each other as they tend to be more rigid and do not deform under heavy load. Also special coating is provided to decrease tool wear and increase tool life and productivity

APPLICATION IN INDUSTRIES-

- MANUFACTURING SECTORS

- MARINE INDUSTRY

- AUTOMOBILE INDUSTRY

- AEROSPACE INDUSTRY

Carbide Center Drills

Expertise :

- Center-drill can both drill and chamfer the top of the hole in one operation.

- Double ended design maximizes tool life.

- Also available in reduced neck diameter.

- Optimized for chucking at any depth due to reduced neck diameter

Description

Center-drill– JP TECH TOOLS’ manufactures center-drill that are used in all metal machining manufacturing industry and we also provide special coating as per our customer’s requirements for less wear which helps in better tool life and productivity.

Center Drills are used for providing centering holes on shaft’s faces, so to hold them between centers for other CNC job work.

APPLICATION IN INDUSTRIES-

- MANUFACTURING SECTORS.

- MARINE INDUSTRY.

- AUTOMOBILE INDUSTRY.

- AEROSPACE INDUSTRY

Burnishing drill

Expertise :

- Burnishing margin helps to create smooth hole

- Special coating increases tool life

- High accuracy

- Axial run-out of less than 2 micron

Description

Burnishing drill— JP TECH TOOL’S burnishing drills allows very accurate sizing of the hole and the burnishing margins create a very fine finish on the inside of the hole. JP TECH TOOLS’ drills are extremely precise when you need multiple holes that are very close in size to each other as they tend to be more rigid and do not deform under heavy load. Also special coating is provided to decrease tool wear and increase tool life and productivity

APPLICATION IN INDUSTRIES-

- MANUFACTURING SECTORS.

- MARINE INDUSTRY.

- AUTOMOBILE INDUSTRY.

- AEROSPACE INDUSTRY